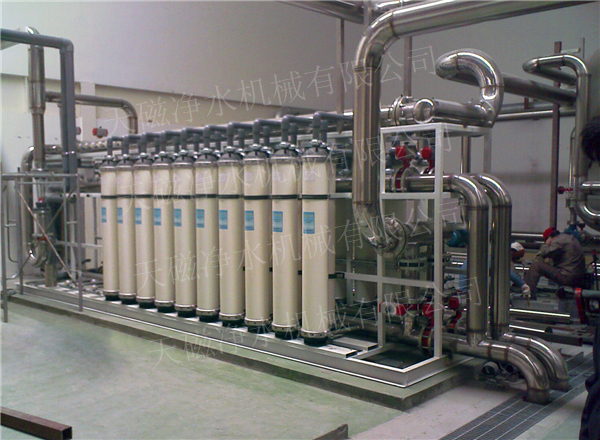

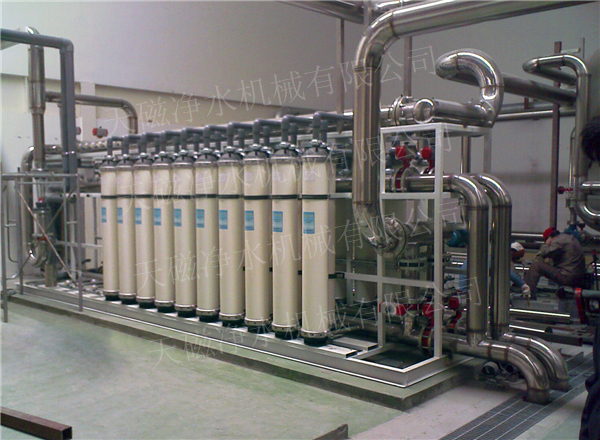

Product introduction

Ultrafiltration is a membrane separation process based on separation principle and pressure-driven filtration. The filtration precision is within the range of 0.005-0.01um, which can effectively remove particles, colloids, bacteria, heat sources and organic macromolecules in water. Can be widely used in material separation, concentration, purification. UF process without phase conversion, operating at room temperature, particularly suitable for the separation of heat-sensitive substances, and has good temperature, acid and alkali resistance and oxidation resistance, can be below 60 ℃, PH 2-11 under the conditions of long-term continuous use.

My company ultrafiltration equipment advantages:

1. UF membrane components using the world's leading membrane company's products to ensure that customers get the world's highest quality organic membrane components, thus ensuring the retention and membrane flux.

2. The system has high recovery rate, the quality of the product is good, which can realize the efficient separation, purification and high-fold concentration of the material.

3. No phase change in the process, no adverse effects on the composition of the material, and separation, purification, concentration process is always at room temperature, especially for the treatment of heat-sensitive substances, completely avoiding the destruction of bioactive substances at high temperatures Drawbacks, effectively retain the original material system of bioactive substances and nutrients.

4. System low energy consumption, short production cycle, compared with the traditional process equipment, equipment operating costs low, can effectively reduce production costs and improve economic efficiency of enterprises.

5. Advanced system technology design, high degree of integration, compact structure, small footprint, easy operation and maintenance, low labor intensity.

6. The control system can be designed according to the specific requirements of the user, combined with advanced control software, on-line centralized monitoring of important process operating parameters, to avoid human error, multi-directional to ensure long-term stable operation of the system.

Scope of application

1, the pretreatment of reverse osmosis equipment, high efficiency, compact ultrafiltration due to high filtration accuracy, reverse osmosis membrane can provide maximum protection;

2, the depth of large and medium-sized drinking water plant processing;

3, municipal and industrial wastewater treatment, ultrafiltration can provide better treatment than the traditional treatment process to achieve water, wastewater reuse;

4, recycled sewage treatment reuse water purification;

5, Sewage recycling of useful substances;

6, mineral water preparation, drinking water, well water removal treatment, removal of water in a variety of suspended solids, colloidal impurities, especially the removal of cryptosporidi, flagellates, E. coli and other pathogenic microorganisms;

7, oral liquid, biological products sterilization, clarification, purification separation;

8, high-purity water terminal processing;

9, fruit juice, protein, enzyme concentration of the separation.